Bolts are a common home repair hardware tool. Whether you’re building a piece of furniture or a larger structure, it’s essential to choose the right bolts for the job. The wrong bolt could lead to a faulty product, which could potentially lead to injury. In this blog post, we will provide a comprehensive guide to choosing the right bolts. We’ll discuss the different types of bolts, factors to consider, and tips for choosing the right bolts. Let’s get started!

Types of Bolts

There are many different types of bolts, each of which has its own advantages and disadvantages. Here are the most common types.

1. Hex Bolts

Hex bolts are among the most widely-used types of bolts, featuring six-sided heads and varying in size and length. These bolts are often employed in construction and machinery projects.

2. Carriage Bolts

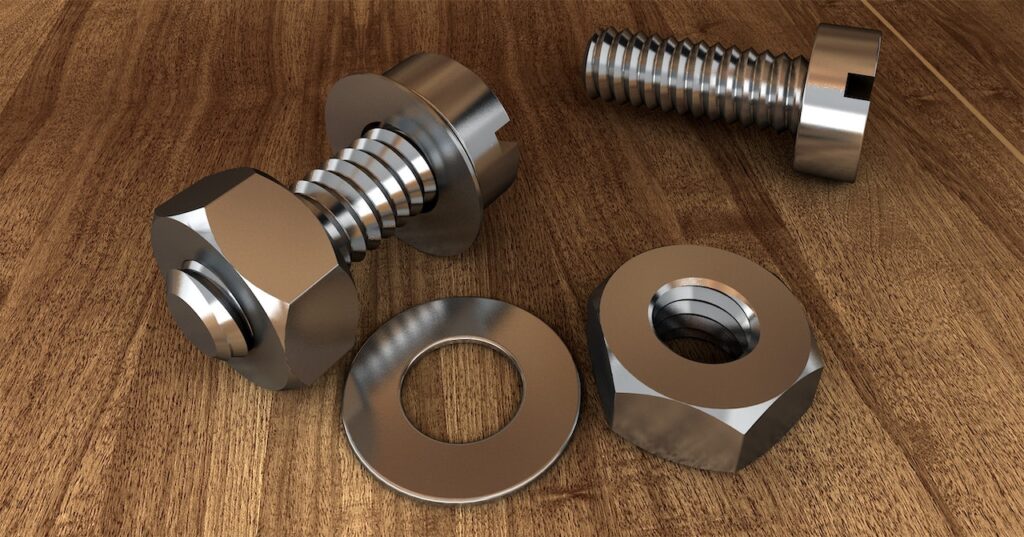

Carriage bolts have round heads and are designed to be used with a nut and washer. They are commonly used in woodworking and construction applications.

3. Lag Bolts

Lag bolts are distinct from hex bolts in that they have a pointed tip and coarse threading. They are primarily used in wood or other soft materials, making them ideal for construction applications.

4. Eye Bolts

Eye bolts have a looped head and are designed to be used with a nut and washer. They are commonly used to attach cables or ropes to a structure.

5. U-bolts

U-bolts have a U-shaped head and are designed to be used with a nut and washer. They are commonly used to secure pipes or tubes to a structure.

6. J-bolts

J-bolts have a J-shaped head and are designed to be embedded into concrete or other materials. They are commonly used in construction applications to secure structures to a foundation.

7. Stud Bolts

Stud bolts have no head and are threaded on both ends. They are designed to be used with nuts and are commonly used in construction and machinery applications.

Overall, each type of bolt has unique characteristics and uses, and selecting the right bolt type is crucial for ensuring the structural integrity and safety of your project.

Materials of Bolts

When selecting a bolt for a project, it is important to consider the properties and suitability of the material for the specific application and environment in which it will be used. Steel is the most widely used material for bolts due to its strength and affordability. It is further divided into different grades, such as Grade 2, Grade 5, and Grade 8, each with varying strength and suitability for different applications.

Steel bolts are often used in construction, automotive, and machinery applications.

Stainless steel is another popular material for bolts due to its corrosion resistance and aesthetic appeal. It is commonly used in applications where the bolt will be exposed to moisture or harsh environments, such as marine or outdoor applications. Stainless steel bolts are available in different grades, such as 18-8 and 316, each with varying levels of corrosion resistance.

Titanium bolts are known for their strength-to-weight ratio and resistance to corrosion. They are commonly used in applications where weight reduction is critical, such as aerospace or sports equipment.

How to Choose the Right Bolt

The right bolt can be a critical decision that can affect the overall strength, durability, and safety of the structure. When selecting the right bolt for a project, several key factors should be taken into account.

- Consider the specific application and the amount of stress the bolt will be subjected to, as well as any environmental factors such as moisture or high temperatures.

- Determine the load capacity of the bolt in relation to the weight and load-bearing capacity of the structure.

- Choose the right size and length of the bolt based on the size and thickness of the materials being fastened.

- Consider the threading of the bolt and make sure it matches the threading of the corresponding nut or hole.

- Take the environment into account when selecting the material and grade of the bolt. For example, stainless steel bolts may be necessary in corrosive environments, while titanium bolts may be necessary in high-temperature environments.

- Make sure to follow industry standards and guidelines to ensure the appropriate use of the bolt and its strength and safety.

By considering these factors, you can choose the right bolt for your project and ensure the safety and durability of the structure.

Here are some similar articles that you might want to read:

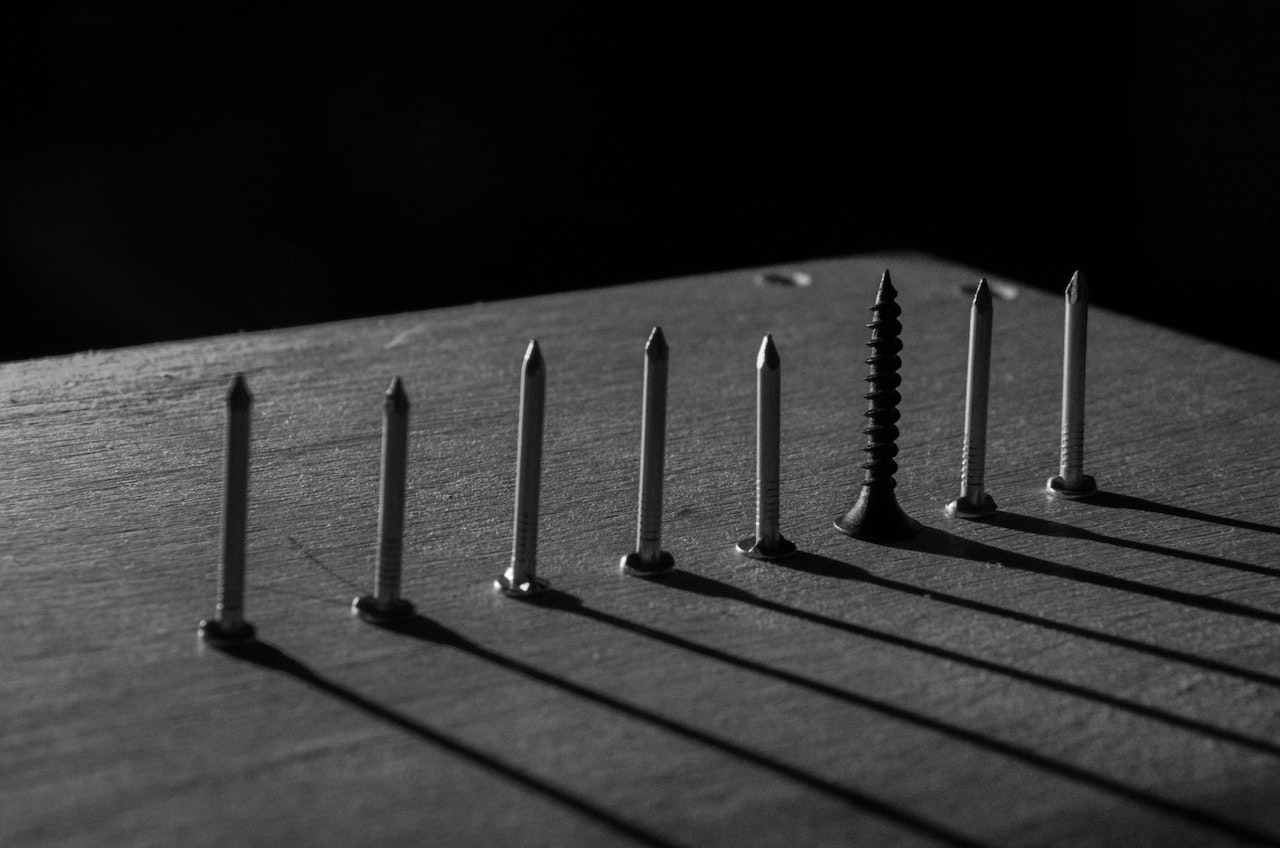

1. An Introduction to Different Types of Screws

2. DIY Guide: How to Install a Shower Door Sweep