Screws are essential tools used for a variety of tasks in many different industries. From basic home repairs to complex construction projects, screws are essential for holding objects together. But it can be difficult to know which one is the best for your project among these types of screws. This post will provide an introduction to different types of screws and explain their uses, so you can choose the right one for your needs. We’ll cover wood screws, sheet metal screws, machine screws, drywall screws, self-tapping screws, lag screws, concrete screws, thumb screws, shoulder screw and set screws. Read on to learn more about each type of screw and get the information to make the right choice.

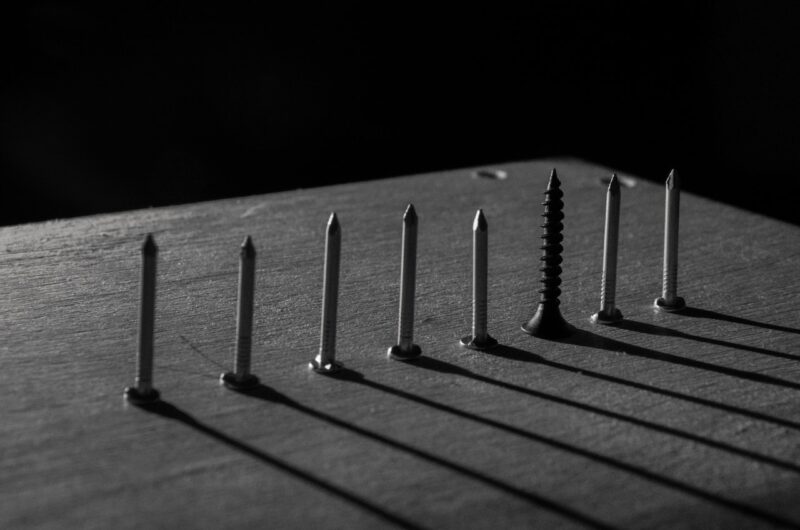

1. Wood Screws

Wood screws are an essential tool for any project involving wood. Their versatility and strength make them ideal for a wide range of uses, from furniture assembly to carpentry. They come in a variety of sizes and styles, with a range of heads, lengths, diameters, and thread pitches to suit different applications. They can be made from steel, brass, or stainless steel, and can be found in different finishes and colors to add a decorative touch. You can secure two pieces of wood, attach hardware to a wooden surface, or create a joint using the right wood screw.

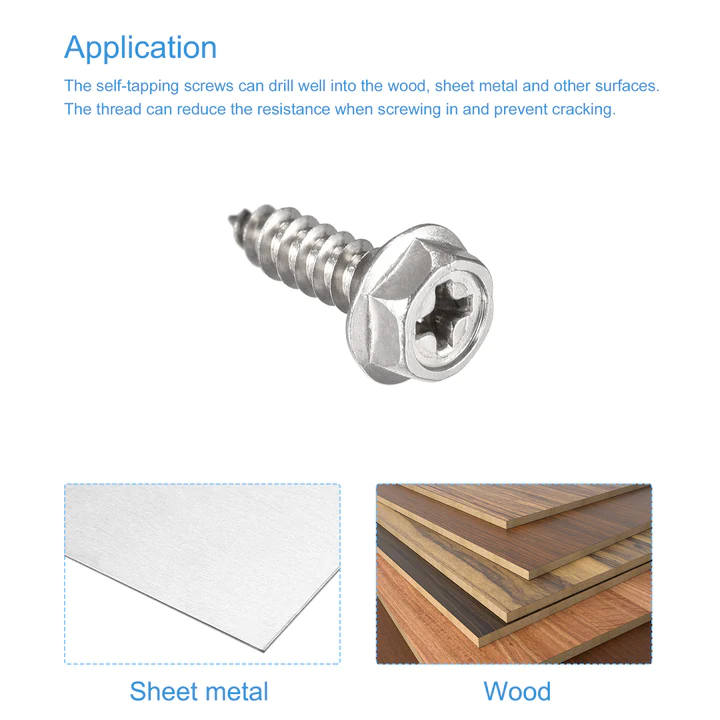

2. Self-tapping Screw

Self-tapping screws are a type of fastener that can create their own thread as they are screwed into a material. Instead of relying on an existing thread or pre-made hole, these screws have a pointed end that is designed to pierce the material and start the threading process. As the screw is turned, the threads on the shank cut into the material, enabling a secure and tight fit without the need for a separate tap or pre-drilling. They come in various sizes, styles, and materials like steel, stainless steel, and brass. They can be used in construction, automotive, and electronics applications, among others.

3. Lag Screw

A lag screw, also known as a lag bolt, is a heavy-duty screw designed for use in wood or other dense materials. It features a thick shank and coarse threads to ensure a secure hold. The head of the lag screw is hexagonal or square, allowing it to be tightened or loosened with a wrench or pliers. This makes it a great choice for any type of construction or other application where a strong and durable fastening is required. Lag screws come in various sizes and lengths for different purposes. They can attach heavy objects to wood or other materials, secure framing or structural components, or join two pieces of wood.

4. Drywall Screw

Drywall screws are specially made for installing drywall or gypsum board. Their unique bugle-shaped head and sharp, self-drilling point allow them to penetrate the drywall surface easily. The tapered head of the screw allows it to be countersunk into the drywall creating a smooth and flush finish. Drywall screws come in different sizes, lengths, thread pitches and materials to suit various applications. They are most commonly used for interior walls and ceilings but can also be used for other projects where a secure fastening is needed in drywall or similar materials.

5. Concrete Screw

Concrete screws are designed to provide a secure and long-lasting fastening option for use in concrete, brick, or masonry materials. They come in a range of sizes and lengths and feature different head styles and materials, such as hardened steel or stainless steel, to ensure they can penetrate hard materials. To install a concrete screw, a hole must first be drilled into the material using a masonry drill bit. The screw is then inserted into the hole and tightened using a wrench or drill, as the threads cut into the material for a tight grip. Concrete screws are commonly used in construction and other heavy-duty applications to install structural components and other heavy objects, or for any application where a strong and secure fastening is needed in concrete or similar materials.

6. Thumb Screw

Thumb screws are designed to be tightened or loosened without the use of any tools. They have a large, flat head with ridges or knurling around the circumference for easy turning with the fingers. These screws come in many different sizes and materials, with various head styles and finishes to meet the needs of any application. The captive thumb screw is one type that is particularly useful, as it has a washer or other component attached to the underside of the head, preventing it from being lost when the screw is removed. Thumb screws are widely used in machinery, equipment, electronic enclosures, and other situations where the use of tools is inconvenient or impractical.

7. Shoulder Screw

Shoulder screws, sometimes referred to as shoulder bolts or stripper bolts, are cylindrical screws that feature a shoulder between the head and the threaded portion. This shoulder serves as a bearing surface and also functions as a precise spacer or stop in mechanical assemblies. They come in a range of materials such as steel, stainless steel, brass, and nylon, and are available with hexagonal, round, socket, or slotted drive heads. The threaded portion of the screw can vary in length, and may be fully or partially threaded depending on the application. Shoulder screws are commonly used in machinery, tooling, and other precision assemblies where alignment and spacing are critical. They can secure components in place, act as pivots or shafts, or provide a smooth bearing surface for rotating components. Some shoulder screws have a knurled or ribbed shoulder for increased grip and handling.

8. Machine screw

Machine screws are a type of screw designed to be used with a nut or tapped hole in a mechanical assembly. They can come in a variety of sizes, materials, and head styles, such as flat, oval, pan, and round heads. Steel, stainless steel, brass, and nylon are all potential materials for machine screws. They are often used to attach components to a base or frame, secure parts together, or offer a threaded anchor point for other components. The versatility of machine screws makes them a popular choice for applications where an exact and secure fastening is necessary.

9. Sheet Metal Screw

Sheet metal screws are an ideal choice for fastening thin materials together. Their sharp, pointed tip and coarse thread enable them to easily penetrate and securely hold the material in place. They come in a range of sizes, materials, head styles, and finishes, and can be used in a variety of applications, including HVAC systems, roofing, gutters, and other sheet metal projects. An added benefit of these screws is that they can self-tap into the material, eliminating the need for pre-drilling. However, it’s important to ensure that they are properly sized and positioned to avoid over-tightening and deforming or cracking the material.

10. Set Screw

Set screws, also known as grub screws, are an efficient and adjustable type of fastening that can be used without a nut or washer. They have a hexagonal or cylindrical head, and are usually made from steel, stainless steel, brass, or nylon. Set screws can be used in a variety of mechanical assemblies, such as gears, pulleys, and couplings, as well as other applications where a precise and adjustable fastening is required.

The main benefit of set screws is the ability to securely fix components without needing a different nut or washer, improving space efficiency and simplifying assembly, especially in tight or hard-to-reach spaces. However, they must be used with caution, as over-tightening can cause damage to the shaft or hole they are threaded into. Therefore, it is important to apply the correct torque when using set screws.

In conclusion, screws are invaluable tools for a wide range of tasks, from basic home repairs to complex construction projects. After reading this article about the different types of screws and their uses, you can choose the right one for your project. From wood screws to concrete screws, sheet metal screws, and more, there is a type of screw to suit any application.

Here are some similar articles that you might want to read:

1. What is Screw

2. A beginner’s Guide to Using Self-Tapping Screws